資源中心

膜科技助力鋼鐵行業(yè)綠色轉(zhuǎn)型,戈?duì)枮V袋打造超低排放熱風(fēng)爐示范案例

案例研究, 689.03 KB

鋼鐵行業(yè)作為國(guó)民經(jīng)濟(jì)的支柱產(chǎn)業(yè),正積極推動(dòng)綠色轉(zhuǎn)型,以實(shí)現(xiàn)更環(huán)保、可持續(xù)的生產(chǎn)模式。該鋼鐵環(huán)保改造案例介紹了江蘇省張家港市某大型民營(yíng)鋼鐵集團(tuán)5800m3高爐熱風(fēng)爐煙氣脫硫項(xiàng)目:如何借助戈?duì)柕南冗M(jìn)過(guò)濾方案實(shí)現(xiàn)了超低排放,為行業(yè)的綠色進(jìn)階發(fā)展貢獻(xiàn)了自身力量。

Case Study: GORE? Low Emission Filter Bags for Titanium Dioxide Products

Case Studies, 166.99 KB

The emissions were eliminated increasing particulate capture efficiency and productivity. Filter bag life increased from 4 to 18 months.

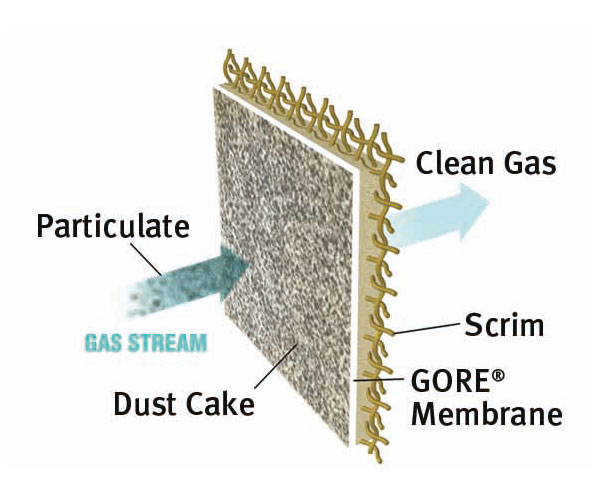

GORE? Membrane Technology vs. Non-Membrane Media: Industrial Baghouse Filters

Technical Information,

Learn the differences between membrane and non-membrane filter media. GORE Membrane Technology provides longer bag life, lower emissions rates, lower pressure drops and better has throughput.

Case Study: GORE? Low Emission Filter Bags in the Cement Industry

Case Studies, 77.48 KB

The plant installed a brand new Fives Solios TGT? baghouse with significant portions of the clean air plenum manufactured from stainless steel construction to prevent corrosion

Article: Filters for NESHAP compliance

Industry Articles, 2.2 MB

In a four page article, Chris Polizzi, W. L. Gore & Associates, USA, addresses how the implications of the National Emissions Standards for Hazardous Air Pollutants (NESHAP) in the USA are far reaching in their targeting to reduce emissions from cement plants to unprecedented lower levels.

Data Sheet: GORE? Low Emission Filter Bags

Data Sheets, 115.12 KB

GORE Low Emission Filter Bags are innovative seam-taped filter bags that provide extremely high filtration efficiency and excellent product capture. They start with a filter bag already proven to provide extremely low emissions and add a newly engineered and patented high-temperature, high-durability seam tape covering all stitches on the filter bag.

Case Study: GORE? Low Emission Filter Bags in Secondary Lead Recovery & Refining

Case Studies, 126.15 KB

An emergency order was placed for GORE? Low Emission Filter Bags. The new filters were rushed to the plant site, where the leaking filters were completely replaced.